|

|

|

|

|

|

|

Everything has some measurable rate of failure. With traditional steel bicycle frames, almost every failure can be rectified and usually at a moderate rate, making steel frame repair a straightforward and economical alternative to frame replacement.

This frame came to us with a crack along the lower headlug.

You can see that this doesn't affect rider safety and there is no further incidental damage. When a downtube cracks, for example, the lugs and/or other joints can be further damaged but most like this one are isolated

The first thing we did was to cut the tube so it's easier to remove. Leaving the tube intact would risk tearing the lugs when the joints are hot and the tube is pulled out. In this case cutting the head tube revealed the reason for failure. The frame was forced into shape and brazed under tension. This can happen when brazing in a solid fixture. Frame brazing fixtures ("jigs") make the work quicker but obviously risk this type of failure. Here we use our frame plate to set the geometry and then tack the joints which means we add a spot of bronze just at the edge of each lug all in the vertical plane. The geometry is checked, alignment is ensured and then we braze free in space so there are no internal stresses. Here is evidence of the error:

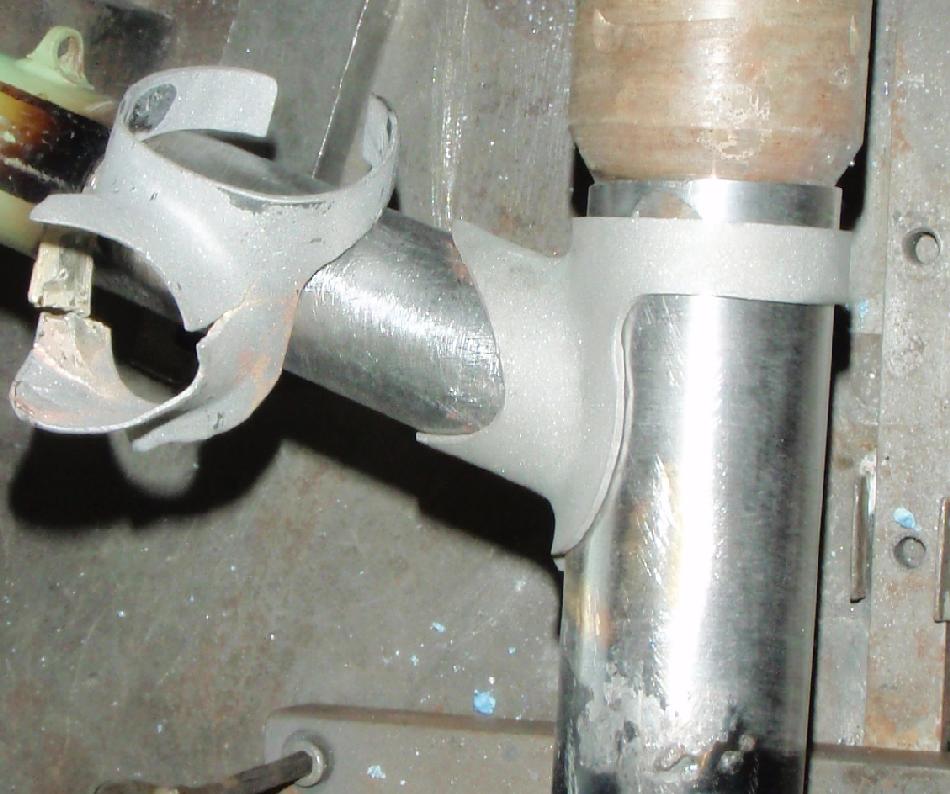

We then coated the head tube with boric acid flux, heated it evenly in firebrick 3/4 the way around. Using a big cool oxygen-propane torch, we are able to bring the entire joint to temperature evenly so the joints can be pulled apart without damage to the tubes or lugs. Note the fronts of the headlugs are sliced to make removal easier and avoid risk of tearing the lug when it is hot.

Once the broken tube is out, we clean off the flux and remove any corrosion or scale so the joint area is nice and clean. Then we acid-wash the joints to get the last bit of crud out of the joint area.

Using a large cool flame in a firebrick border, we are able to fill the joints with fresh bronze that runs easily through the lugs when everything is clean and warm. Bronze is added on one side of a lug and pulled right through to the other side, ensuring the whole joint is fully brazed. Builders who use a small hot flame like oxygen-acetylene or oxygen-MAPP have a more difficult time of getting a wet uniform flow through the whole joint. Once everything is clean and hot, the bronze runs between the lug and tube by capillary action, leaving a nice meniscus at the edges of the lugs.

After filling the joint the frame is encrusted with flux which has carried the black oxides off the surface of the metal. Looks ugly here, but as the flux is removed, the underlying metal is a beautiful shiny steel grey with nice warm gold brazed areas.

After cleanup we machine the headset bearing seats with our Campagnolo Titanium Nitride cutters so the headset runs true

Aerosol primer/color is free if you wish or a real paint job can be applied now because this bike is done!

Hey here's another We do track ends in steel frames too! Dents filled in metal, not plastic

Broken

Broken

New tube brazed

New tube brazed

Cleaned & filed

Cleaned & filed

Done!

Done!

Dented Head Tube

Dent!

Dent!

Dent!

Another Head Tube

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

Broken

D E N T S

click for larger image

Let's see one more!

Bianchi Eros

Let's see just one more!

Click Big

Click Big

Click Big

Click Big

Click Big

Click Big

Click Big

Click Big

British RALEIGH

Click Big

Click Big

Click Big

Click Big

We can rebuild your bike too!

Let's see just one more!

Click Big

Click Big

Click Big

Click Big

Click Big

Click Big

One mre Bianchi

![]()

how to order

aluminum frame repair services

More Frame Repair

more frame service

or just click the Service gear on the upper left of this page.

Click to consult about

frame repair services at Yellow Jersey

Frames ship quickly and cheaply via insured UPS

MORE DENTS HERE