|

|

|

|

|

|

|

When tourists first clamored for more than one gear clever designers developed hubs with a gear on each side and later William Reilly's creative mind gave us the wonderful SturmeyArcher planetary geared hubs. The French, however, got modern bicycle touring off the ground with multiple-cog freewheels and derailleurs to push the chain from one gear to another. This all worked up from three to the classic four speed and in my youth even (cycling's "killer app" of the fifties!) TEN SPEED systems with five cogs mounted on a ratcheting freewheel assembly. .

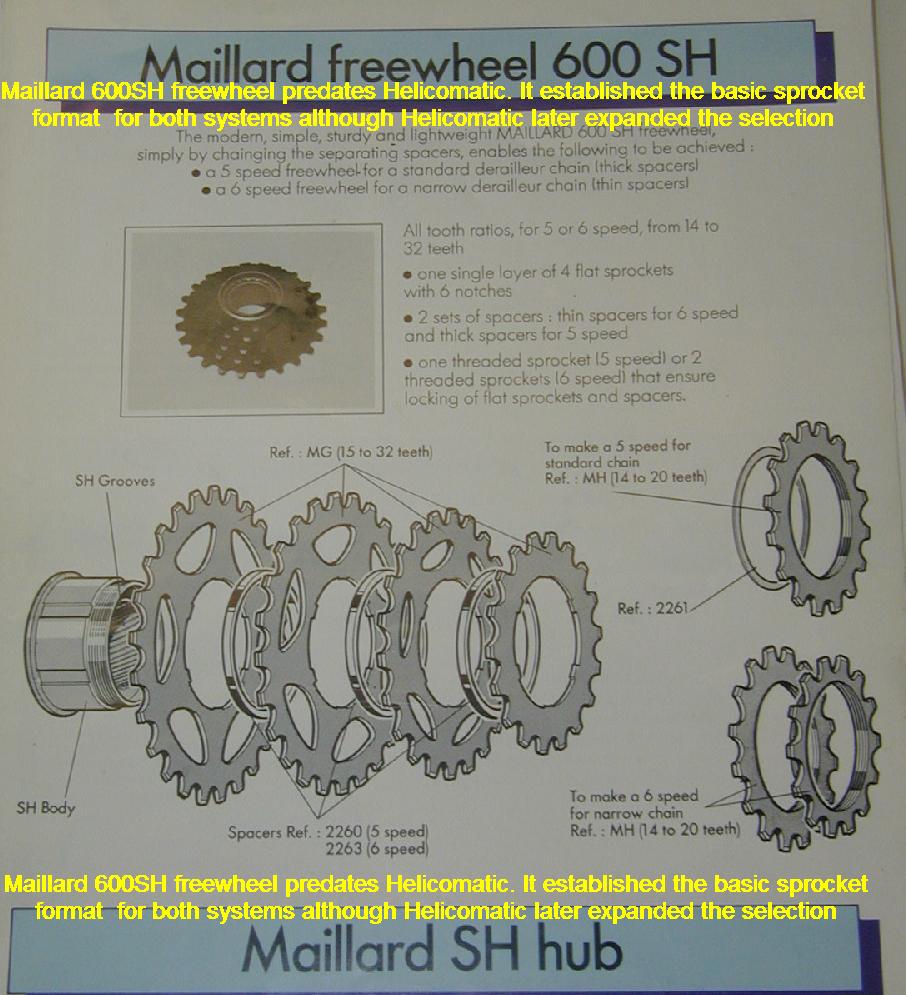

It was the French again who addressed the classic freewheel's foibles with Maillard's Helicomatic of the late seventies. Freewheels are notoriously difficult to remove as the piece is screwed tight to the threaded hub with all the might of a rider standing on the pedals in low gear. Classic Regina, Cyclo and Merveille freewheels typically have two small notches in the thin hardened lip of the freewheel body. A dry thread and years of use often required breaking the freewheel body to remove it for a simple spoke replacement after the removing tool had shattered the little notches. Better splined bodies and tools appeared at the end of the Sixties. Probably the best designed setup was, as usual, Maillard's big 30mm freewheel body with 24 splines. For the first time, we did not have to remove the axle to get a removing tool into the body! In 1971, the left coast's cycling genius Phil Wood made a thin wall removing tool for Maillard's other freewheel, the M M Atom which came on millions of bike-boom bikes from France's incomparable Peugeot PX-10 all the way down to the Schwinn Varsity. That breakthrough even influenced Regina to adopt Atom's small spline format.

We break here to cover Maillard's product line in the classic era. Amalgamating several small houses into one of cycling's powerhouses of the era, Maillard made small-flange hubs under the M M Atom label, high flanged hubs marked "Normandy", track hubs in both series, a workhorse quick release skewer for both lines stamped "M M Atom", Atom freewheels of four five and six speeds both with splines and with two-notch bodies, large spline Maillard-Normandy freewheels, an Atom drum brake hub range for everything from Schwinn's Orange Crate to tandems and mopeds, and nice midprice pedals including big wide Atom 400s and the cute racy Atom 440s that graced the Raleigh Super Course. America was awakening to real bicycles and her appetite was enormous. Tens of millions of "ten speeds" landed here every year, many sporting that Maillard equipment which was the benchmark stuff in a crowded market. All that volume put Maillard in a position to develop new products for an industry long-sclerotic but now revitalized.

And develop they did! The French needed to move up the quality scale from the commodity end of the business. Other lower-cost newcomers such as Sunshine and Suzue, Mikashima and Kyokuto, Shimano and Maeda/Suntour were beginning to nip at her heels with better quality equipment. Japanese manufacturers were also bolstered by an artificially cheap yen (over 300 to a dollar!). But Maillard still had volume and the cash to experiment. Maillard remade the Luxe Competition hubs with better seals and finish and went on to introduce a new product range, the 700 Professionnel. Hubs finally got substantive bearing quality upgrades and Maillard debuted the first aluminum body freewheel with aluminum cogs under the 700 Professionnel marque. Unfortunately the available materials were not yet ready and the excessive heat treatment was not enough to cover rapid cog wear. Moreover, the design didn't lend itself to a splined remover and in spite of an excessively done expensive remover, the two-notch bodies split open in our service department..

Shimano had brought out their first cassette hub by then. The early effort used a two-piece hubshell with a ratcheting body stamped into them. The last cog screwed onto the body before the idea of an outer lockring had occurred to them. Quality was minimal but the pattern got established

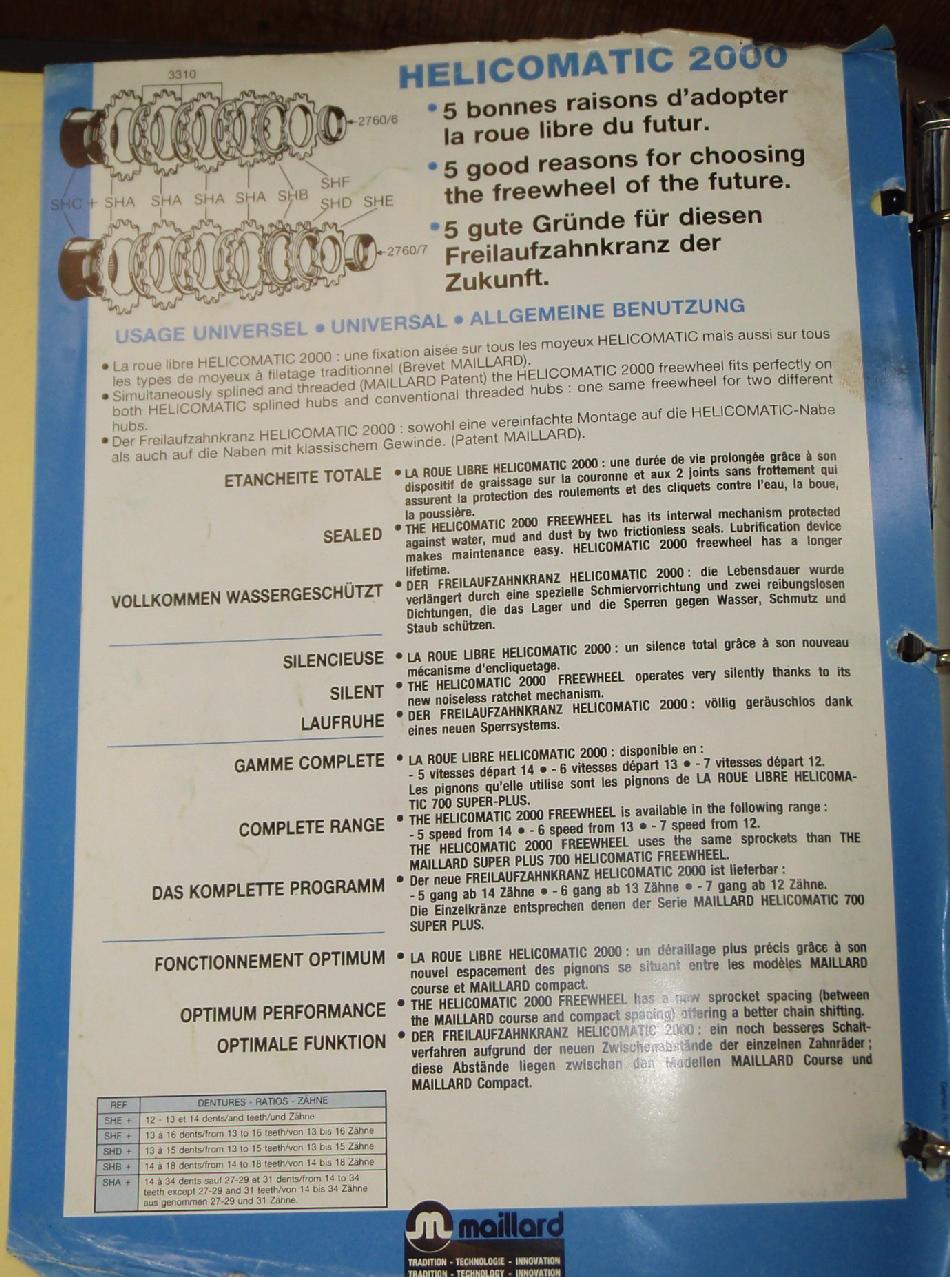

Which brings us finally to Helicomatic. As you can see above the freewheel was easily removable

with a high-helix set of splines. For the first time cycle tourists could

replace spokes with only a small key for the lockring and little effort.

Instead of screwing cogs from the front and (reverse thread!) the back, all the cogs slipped easily off the body once the first was unscrewed and custom gearing came without suffering. Notably, the outer bearing moved from under the right flange out to the end below high gear. Broken axles, which were a problem with four and five speed freewheels, were becoming a plague to six and the new seven cog systems. Now the axle was correctly supported with no cantilevered end to crack off. Even more cleverly, Maillard used the same axles and cones, just without the big right-side axle spacers. Since Maillard- Atom-Normandy had enjoyed the number one position in the hub market for many years, tens of thousands of bicycle shops worldwide had service parts on the shelf already when the Helicomatic appeared. The same axle sets fit all hub models, new and old (except the Luxe Comp and Professionnel oddities). The removing tool was dirt cheap - so much so that you got one free with your new Helicomatic bicycle. And the cute remover included two spoke keys and a bottle opener! Helicomatic ranges include the standard quality "Sport" equipment, a better-polished bearing models "500" and the "600" . Top line "700 Professionel" use 10x3/16" balls with unique cones ^ axles. The later 700 Professionnel also wandered into an ultra-fine axle thread for no apparent reason. Later models progressed to well-designed chromed labyrinth seals with an upturned lip on the hub side and an inward-facing cap on the cone..

- We have support for Helicomatic systems including:

- Helicomatic remover tools $24.95

- Helicomatic remover includes bilingual directions

- Helicomatic splined cogs $29.95

- Helicomatic threaded cogs $29.95

- Newly arrived sprockets - now all sizes in stock five, six and seven speed

- Helicomatic cog spacers $4.95

- Helicomatic lockrings $39.95

- Helicomatic hub seals $4.95

- Helicomatic axle cone seals $4.95

- Helicomatic adapter ; fits Maillard freewheel on Helicomatic hub $-out-

- Helicomaticfreewheel body, 6 or 7 $-out-

- Helicomaticcomplete six freewheel $-out-

- Helicomatic complete seven freewheel $-out-

- Helicomatic Pro 700 front axle set with seals $49.95 also fits Normandy Competition front

- Helicomatic Sport front axle set including hub* $39.95

- Helicomatic Sport rear axle set including FW hub * $59.95

- Helicomatic Sport rear axle set including Helico hub $89.95-

- Helicomatic Pro rear axle set including Pro hub $ -all sold-

| * These hub axles interchange perfectly to early Helicomatic Sport hubs with 1/4" balls. Too big for the later 5/32" ball models. The models Helicomatic 500 and Helicomatic 600 use a different and not available cone . Top quality highly polished 700 Professionnel Helicomatic hubs use both an unusual cone and a uniquely fine threaded axle . We have new Pro hubs again for these. 700Pros use a larger chromed locknut in that special thread. Type Sport, 500 and 600 use smaller 5/32"x13 ball bearings. 700 Professionnel take 3/16"x10. If you open your rear hub and see nine bearings which are 1/4", then you have an early model Sport hub and this is the correct axle set. If it's 13x 5/32" balls, we have no cones or axle sets. SAdly now out of 700 Pro rear hubs. |

We no longer have n.o.s. Helico

freewheel bodies. Help! I need email advice on my Helico setup!

New arrival!

Maillard - Atom - Normandy Competition - Professionnel front axle sets!

please click for larger image

Fits all Comp and Pro model front hubs with fine thread $49.95.

For early flat-dustcap "Luxe Competition" models, remove the chromed seals.

No more

Helicomatic Freewheel Adapter, it is only useful with freewheels such as the discontinued Normandy because you need 34mm of free diameter. Most modern freewheels only have clearance of 23mm so the adapter cannot fit through it.

BMX single speed freewheels fit adapter, no problem!

You may always send us an email for some commiseration

Our cog selection is quite broad. We have virtually every Helicomatic sprocket ever made.

![]()